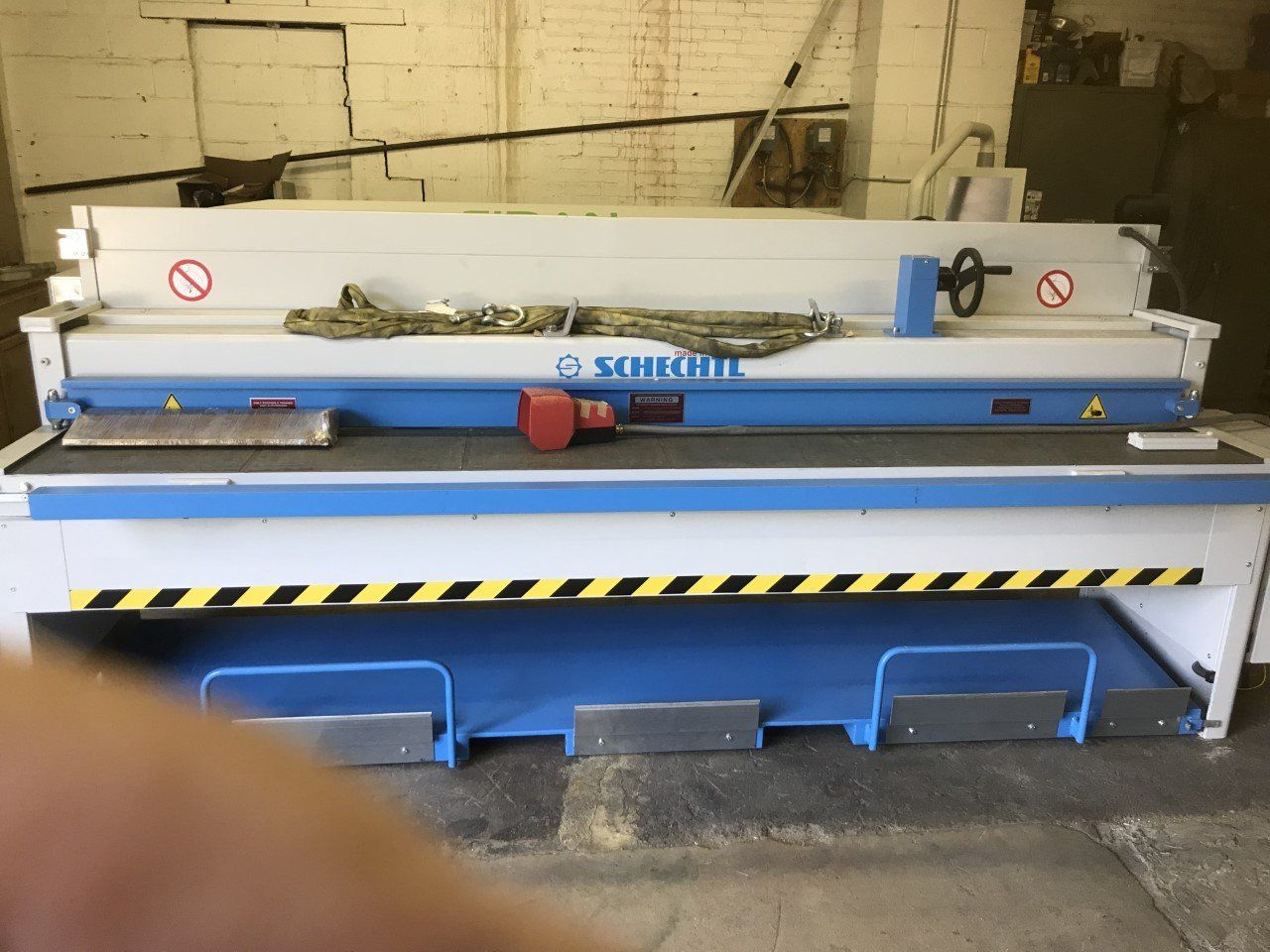

SCHECHTL SMT METAL SHEAR More than 100 years after the company was founded in Germany, the sheet metal shears produced by Schechtl continue to be the leading architectural shears in the industry. These shears are the best on the market.

Today, there are three series of Schechtl Shears available, for light, medium and heavier gauge cutting. Model SMT3100 is a motor driven plate shear designed for 16 ga., MSB for 14 ga. and MSC for 11 ga. Choose from 13 models, with cutting lengths of 40″, 60″, 80″, 122″, 159″ and 174″.

Schechtl shears feature a deeper back-gauge of 30″ (instead of 24″), a rollout wagon (so you don’t have to unload the machine from your knees) and telescoping front support arms.

The telescoping front sheet support makes it a breeze for one operator to handle even 5’ by 10’ metal sheets. This clever system moves in with the sheet as it is cut.

Handling is simple: Put the metal sheet onto the table, push it between the cutting bars and start the process with the foot switch – that’s all.

The machine frame is a sturdy welded steel design. The cutting bar is driven by a noiseless gear motor. All bearings and guideways are maintenance-free.

On each side of the cutting table there are rectangular gauges with a scale of 400 mm (stainless steel). During the cut, a mechanical hold-down bar with non-skid lining holds the part.

The support bar in front of the machine enlarges the area of support to 920 mm (36″).